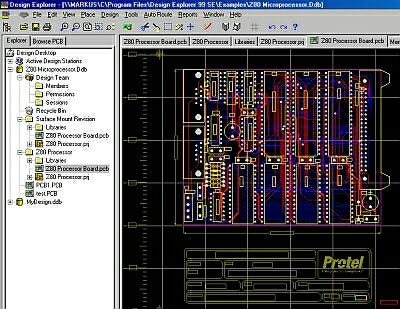

When the size of the circuit board is larger than 200 mm × 150 mm, the mechanical strength of the circuit board should be considered. The best shape of the circuit board is rectangle, and the aspect ratio is 3:2 or 4:3. In general, the wiring range specified in the prohibited wiring layer is the size of the circuit board size. It is necessary to determine the size of the chassis before determining the size of the circuit board, otherwise it is impossible to determine the size of the circuit board. When designing a circuit board with a chassis, the size of the circuit board is also limited by the size of the chassis. The larger the area is, the higher the cost is. The production cost of circuit board is related to the area of circuit board. However, if the size of the circuit board is too small, the heat dissipation is poor, and the adjacent wires are easy to cause interference. The thickness of common circuit boards are 0.5mm, 1.0mm, 1.5mm and 2.0mm Considering the cost, copper wire length and anti noise ability, the smaller the size of the circuit board, the better. The main thing is to ensure enough stiffness and strength. The thickness of the circuit board should be determined according to the function of the circuit board, the weight of the installed components, the specification of the circuit board socket, the overall dimension of the circuit board and the mechanical load it bears. These circuit boards are laminates immersed in flame retardant resin. In the electronic equipment that requires flame retardant, flame retardant circuit boards are also needed. UHF circuit board is best copper coated PTFE glass cloth laminate. The glass cloth laminate impregnated with epoxy resin is less affected by moisture. Epoxy resin and copper foil have excellent adhesion, so the adhesion strength and working temperature of copper foil are higher, and it can not blister in molten tin at 260 ℃. Different laminates have different characteristics. The commonly used copper clad laminates are copper clad phenolic paper laminate, copper clad epoxy paper laminate, copper clad epoxy glass cloth laminate, copper clad epoxy phenolic glass cloth laminate, copper clad polytetrafluoroethylene glass cloth laminate and epoxy glass cloth for multilayer printed circuit board. The selection of laminate should be considered from the aspects of electrical performance, reliability, processing requirements and economic indicators. The general principles of PCB design include: PCB selection, PCB size, component layout, wiring, pad, filling, jumper, etc.Ĭircuit board is usually made of copper clad laminate. Protel DXP provides a comprehensive design solution through the integration of design input simulation, PCB drawing and editing, topology automatic routing, signal integrity analysis and design output. New customizable design environment features include dual display support, fixed, floating and pop-up panels, powerful filtering and object positioning functions, and enhanced user interface. Protel DXP, as a new circuit design software, adds many new functions to the previous version. It can handle all kinds of Complex PCB design processes.

Protel DXP runs on an optimized design browser platform and has all the advanced design features of today. Electronic designers can implement their own design methods from the initial project module planning to the final production data. Protel DXP is the first board level design system that integrates all design tools.

0 kommentar(er)

0 kommentar(er)